- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings

steel structure workshop prefabricated

| Share | |

|---|---|

| Categories | Steel Structure Buildings |

| Trademark/Brand | ZYM steel structure building Manufacturer |

| Model | ZYM1 |

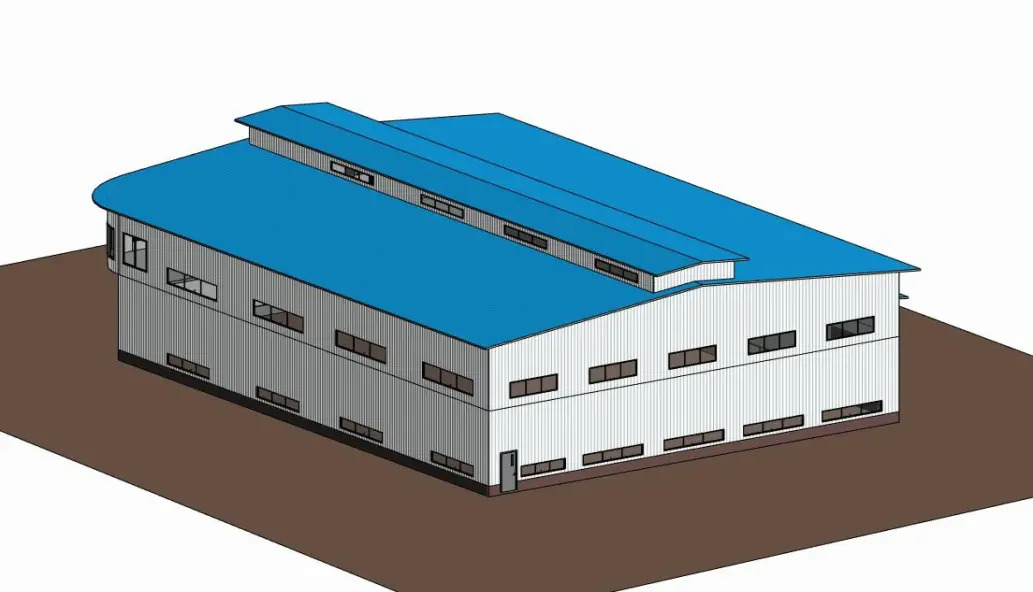

| Name | Indonesia steel structure warehouse workshop |

| Key word | Indonesia steel structure workshop with office |

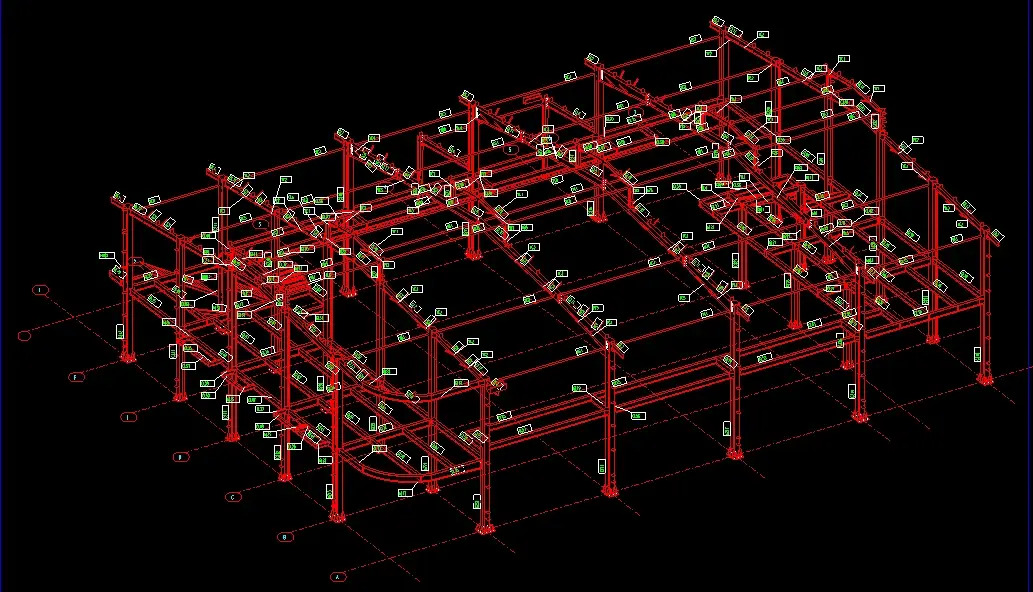

| Design | 3D max,CAD for steel structure frame |

| Material | Q235,Q345B,SS400 steel structure |

| Foof | Galvanized color sheet or sandwich panel |

| Wall | Galvanized sheet for steel structure workshop |

| Place of project | Indonesia steel structure workshop and warehouse |

| Delivery time | 30 days after steel structure drawing confirmation |

| Package | Steel structure frame pallet for 40HQ container |

| Application | workshop,warehouse,office,commercial bulding,shop |

| FOB port | Qingdao Guangdong Shanghai |

| Terms of Payment | L/C, D/A, Western Union, T/T |

| Update Time | Jan 25,2026 |

ZhengYuanming Construction Engineering Co., Ltd.. founded in 2003, is one of the top professional enterprise that specialized in steel structure designing,manufacturing, processing and installing various steel structure projects,such as Low cost steel frame workshop,prefab steel structure warehouse,Prefab Steel Structure Stone Workshop,multifloor light steel structure warehouse,prefabricated steel structure,multi storey steel structure building,Single steel structure warehouse. Through efforts of all staff for 15 years,the products have been exported to over 40 different countries and areas around the world.such as Djibouti etc we have 5 steel structure production lines. ZYM covers an area of more than 50,000 square meters, with excellent equipment, numerical control technology and high degree of automation. Our products are approved by PHI,TUV,BV,CE etc.

| Product name |

steel structure workshop prefabricated |

|---|---|

| Brand Name |

ZYM |

| Material |

high strength steel plate,nut etc |

| Brand |

ZYM steel structure workshop prefabricated Manufacturer |

| Keyword |

Workshop Recyclable Steel Structure,steel frame agricultural building,economic steel structure warehouse |

| Material |

Q235,Q345B,SS400 steel structure |

| Delivery time |

30 days after steel structure drawing confirmation |

| Certificate |

PHI,TUV,BV,CE etc. |

| Package |

Steel structure frame pallet for 40HQ container |

| OEM&ODM |

YES |

| Application |

steel structure building manufacturer in china,simple steel structure warehouse design,prefabicated steel st,steel building beam structure |

| FOB port |

Qingdao Guangdong Shanghai |

| Terms of Payment |

L/C, D/A, Western Union, T/T |

| FOB port |

Qingdao Guangdong Shanghai |

| Processing Service |

Bending, Welding, Cutting, Punching, Pre-assembling, Painting |

| Project Solution Capability |

graphic design, 3D model design, total solution for projects |

| Main Materials |

light steel construction |

| Color |

Request, colorful |

| Design Style |

Modern |

| Characteristics |

Safe foundation, anti-seismic and windproof |

| Sales country |

Micronesia, Federated States of,Seychelles,Saint Helena,Ukraine,Coral Sea Islands,American Samoa,Falkland Islands |

High quality carbon structural steel and alloy structural steel

Prefabricated workshop

ZYM provide the integrated solutions for our clients . After the steel structure design , we arrange the steel Low cost steel frame workshop,prefab steel structure warehouse,Prefab Steel Structure Stone Workshop,multifloor light steel structure warehouse,prefabricated steel structure,multi storey steel structure building,Single steel structure warehouse . In the process , we provide the best quality steel structure and the quality is approved steel structure workshop prefabricated services FAQs GuideAre you looking for a quick review guide about steel structure workshop prefabricatedservices?An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding steel structure workshop prefabricated services.Let’s continue!

2.What type of steel is used in the construction of steel structure workshop prefabricated?

3.Can steel structure workshop prefabricated be expanded or modified in the future?

4.What are the most common applications for steel structure workshop prefabricated?

5.Are there any limitations on the design possibilities for steel structure workshop prefabricated?

6.How does the weight of a steel structure building affect site preparation and construction?

7.What safety precautions should be taken when working on a steel structure building?

8.What is Steel Structure and How Does it Differ from Traditional Construction?

9.Can steel structure workshop prefabricated be relocated or disassembled?

10.What is the maximum height that can be achieved with a ?

11.What type of maintenance is required for steel structure workshop prefabricated?

12.Can steel structure workshop prefabricated be customized to fit specific design requirements?

13.What type of foundation is required for a steel structure building?

14.What are the advantages of prefabricated steel structure workshop prefabricated?

1.How do the construction time and labor costs for steel structure workshop prefabricated compare to traditional building methods?

Our steel structure workshop prefabricated products undergo strict quality control to ensure customer satisfaction. Steel structure buildings typically require less time and labor costs than traditional building methods. Steel structures are typically pre-engineered and pre-fabricated, meaning that much of the work is done off-site in a factory setting. This reduces the amount of time and labor needed on-site, as well as the amount of waste generated. Additionally, steel structures are often easier to assemble than traditional building methods, which can further reduce labor costs.

2.What type of steel is used in the construction of steel structure workshop prefabricated?

We adhere to the principle of integrity and transparency, and establish long -term relationships with partners, and we attach great importance to this detail. The most common type of steel used in the construction of steel structure buildings is mild steel, also known as low carbon steel. Other types of steel that may be used include high-strength steel, stainless steel, and weathering steel.

3.Can steel structure workshop prefabricated be expanded or modified in the future?

We operate our steel structure workshop prefabricated business with integrity and honesty. Yes, steel structure buildings can be expanded or modified in the future. Steel is a very strong and durable material, so it can easily be modified to accommodate changes in the building's design or purpose. Steel structures can be expanded by adding additional steel components or by welding new steel components to existing ones. Steel structures can also be modified by cutting, welding, and bolting new components into place.

4.What are the most common applications for steel structure workshop prefabricated?

We have a good reputation and image in the industry. The quality and price advantage of steel structure workshop prefabricated products is an important factor in our hard overseas market. 1. Warehouses 2. Industrial Buildings 3. Agricultural Buildings 4. Retail Stores 5. Offices 6. Aircraft Hangars 7. Churches 8. Garages 9. Sports Facilities 10. Carports

5.Are there any limitations on the design possibilities for steel structure workshop prefabricated?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers. Yes, there are several limitations on the design possibilities for steel structure buildings. These include the availability of steel, the cost of steel, the weight of the steel, the strength of the steel, the size of the steel, the shape of the steel, the welding techniques used, and the fire resistance of the steel. Additionally, local building codes and regulations may also limit the design possibilities for steel structure buildings.

6.How does the weight of a steel structure building affect site preparation and construction?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of steel structure workshop prefabricated products. The weight of a steel structure building affects site preparation and construction in several ways. First, the weight of the steel structure must be taken into account when designing the foundation and other structural elements. The foundation must be designed to support the weight of the steel structure, and the soil must be able to bear the load. Additionally, the weight of the steel structure must be taken into account when designing the crane and other lifting equipment used to move the steel structure into place. Finally, the weight of the steel structure must be taken into account when designing the temporary bracing and other support systems used during construction.

7.What safety precautions should be taken when working on a steel structure building?

We have established a good reputation and reliable partnerships within the steel structure workshop prefabricated industry. 1. Wear appropriate safety gear, such as hard hats, safety glasses, and steel-toed boots. 2. Use appropriate fall protection equipment, such as safety harnesses and lanyards. 3. Use appropriate tools for the job, such as wrenches, hammers, and saws. 4. Secure all tools and materials to prevent them from falling. 5. Follow all safety protocols and procedures. 6. Inspect the structure for any signs of damage or wear before beginning work. 7. Be aware of your surroundings and watch out for any potential hazards. 8. Use appropriate lifting techniques to prevent injury. 9. Use appropriate scaffolding and ladders to reach higher areas. 10. Disconnect all power sources before beginning work.

8.What is Steel Structure and How Does it Differ from Traditional Construction?

We should perform well in market competition, and the prices of steel structure workshop prefabricated products have a great competitive advantage. Steel structure is a type of construction that uses steel as the primary structural element. It is typically used for large buildings and bridges, and is becoming increasingly popular for residential and commercial construction. Steel structure differs from traditional construction in that it uses steel components instead of wood, concrete, or other materials. Steel structure is lighter, stronger, and more durable than traditional construction, and is also more cost-effective. Steel structure also requires less maintenance and is more resistant to fire, wind, and other natural disasters.

9.Can steel structure workshop prefabricated be relocated or disassembled?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services. Yes, steel structure buildings can be relocated or disassembled. Steel structures are designed to be easily dismantled and reassembled, making them ideal for relocation. Steel structures can be disassembled and reassembled quickly and easily, making them a great option for businesses that need to move or expand.

10.What is the maximum height that can be achieved with a ?

We focus on providing high steel structure workshop prefabricated quality products and services. The maximum height of a steel structure building is determined by the strength of the steel used, the design of the building, and local building codes. Generally, steel structures can reach heights of up to 30 stories or more.

11.What type of maintenance is required for steel structure workshop prefabricated?

We enjoy high authority and influence in the industry and continue to innovate products and service models. Steel structure buildings require regular maintenance to ensure they remain structurally sound and safe. This includes inspecting the building for signs of corrosion, checking for loose or damaged fasteners, inspecting the roof and walls for signs of wear, and inspecting the foundation for signs of settlement or cracking. Additionally, it is important to regularly inspect the building for signs of pests or other infestations, and to check for any signs of water damage.

12.Can steel structure workshop prefabricated be customized to fit specific design requirements?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market. Yes, steel structure buildings can be customized to fit specific design requirements. Steel structure buildings are highly customizable and can be designed to meet the exact needs of the customer. Steel structure buildings can be designed to fit any size, shape, or style, and can be customized with a variety of features such as windows, doors, insulation, and more.

13.What type of foundation is required for a steel structure building?

We are a professional steel structure workshop prefabricated company dedicated to providing high quality products and services. The foundation type required for a steel structure building will depend on the size and type of building, as well as the soil conditions of the site. Generally, steel structure buildings require a concrete slab-on-grade foundation, a shallow foundation, or a deep foundation.

14.What are the advantages of prefabricated steel structure workshop prefabricated?

We continue to invest in research and development and continue to launch innovative products. 1. Cost-Effective: Prefabricated steel structures are cost-effective and can be built quickly, saving time and money. 2. Durability: Steel is a strong and durable material that can withstand harsh weather conditions and is resistant to fire, termites, and other pests. 3. Flexibility: Prefabricated steel structures can be easily modified and adapted to fit any design or purpose. 4. Eco-Friendly: Steel is a recyclable material, making it an environmentally friendly choice for construction. 5. Low Maintenance: Steel structures require minimal maintenance and are easy to clean and repair. 6. Versatility: Prefabricated steel structures can be used for a variety of applications, from residential to commercial and industrial.

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings