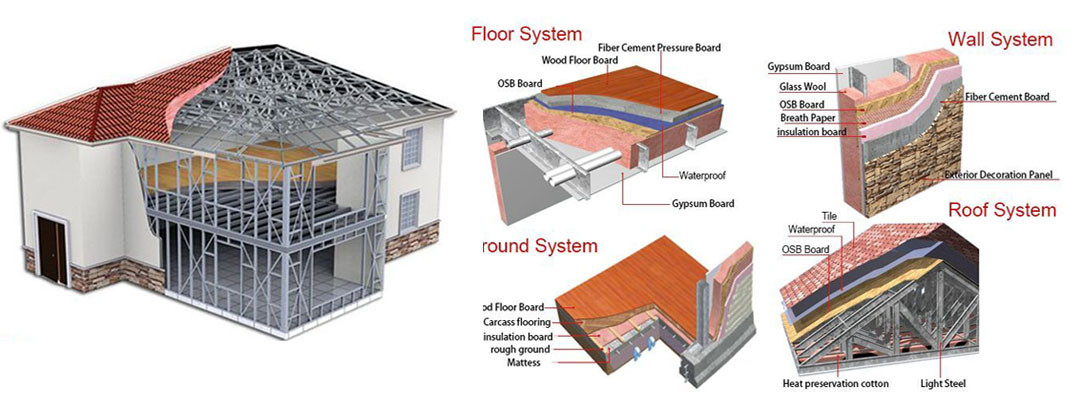

What is the light steel structure building ?

Light steel villa, also known as light steel structure house, it is made of the light steel ,and have the full prefab house system ,so it has the outstanding advantages over the traditional house .

light steel structure building mainly used for civil house such as: prefab house ,villas,offices ,dorimitory ,shops ects.Light steel structure buildings materials ranges from different kinds according to different building requirements.

The light steel structure building have the following features:

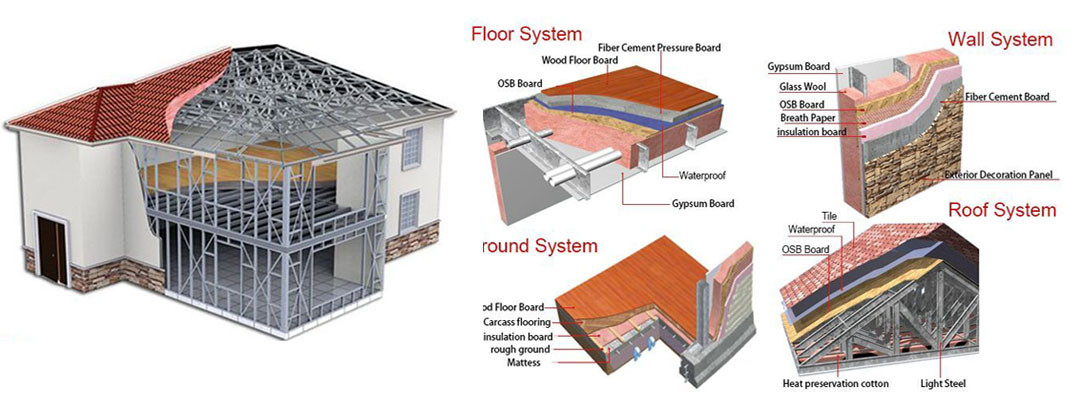

Earthquake resistance: Most roofs of low-rise light gauga steel(Lgs) villas are sloping roofs. Therefore, the roof steel structure basically adopts a triangular truss system made of cold-formed steel The light steel component form a very strong structure after sealing the structural plates and gypsum boards. Rugged "ribbed structural system", this structural system has stronger ability to withstand earthquakes and resist horizontal loads, and is suitable for areas with seismic intensity of 8 degrees or more.

Durability: The light steel structure for residential is composed of cold-formed thin-walled steel component system. The steel bone is made of super anti-corrosion high-strength cold-rolled galvanized sheet. It can effectively avoids the influence of corrosion to the steel plate during construction and use, and increases the life of light steel component. The structural life can reach 100 years.

Insulation: The thermal insulation material used is mainly made of glass wool, which has good thermal insulation effect. With the insulation board of the outer wall, the "cold bridge" phenomenon of the wall is effectively avoided, and a better heat preservation effect is achieved. The thermal resistance of R15 insulation cotton with a thickness of about 100mm can be equivalent to a brick wall of 1m thick.

Sound insulation: The sound insulation effect is an important indicator for evaluating the house. The windows installed in the light steel system are all insulated glass, with good sound insulation more than 40 decibels. The wall made of light steel keel and thermal insulation gypsum board is soundproofed. The effect can be as high as 60 decibels.

Health: Whole dry work construction, reduce the waste pollution to the environment, housing steel structure materials can be 100% recycled, and other supporting materials can also be mostly recycled, with current environmental awareness; all materials are green building materials to meet ecological requirements, good for health

Comfort: The light steel wall adopts high-efficiency energy-saving system, which has breathing function and can adjust the indoor air dry humidity; the roof has ventilation function, which can form the flowing air between the interior of the house to ensure the ventilation and heat dissipation requirements inside the roof.

Fast installation: All dry work construction is not affected by the environmental season.For example one building of about 300 square meters, only 6 workers and 30 working days can complete the whole process from foundation to decoration.

Environmental protection: The material can be 100% recycled, truly green and non-polluting.

Energy-saving: All adopt high-efficiency energy-saving walls, which have good insulation, heat insulation and sound insulation effects, and can reach 50% energy-saving standards.