- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings

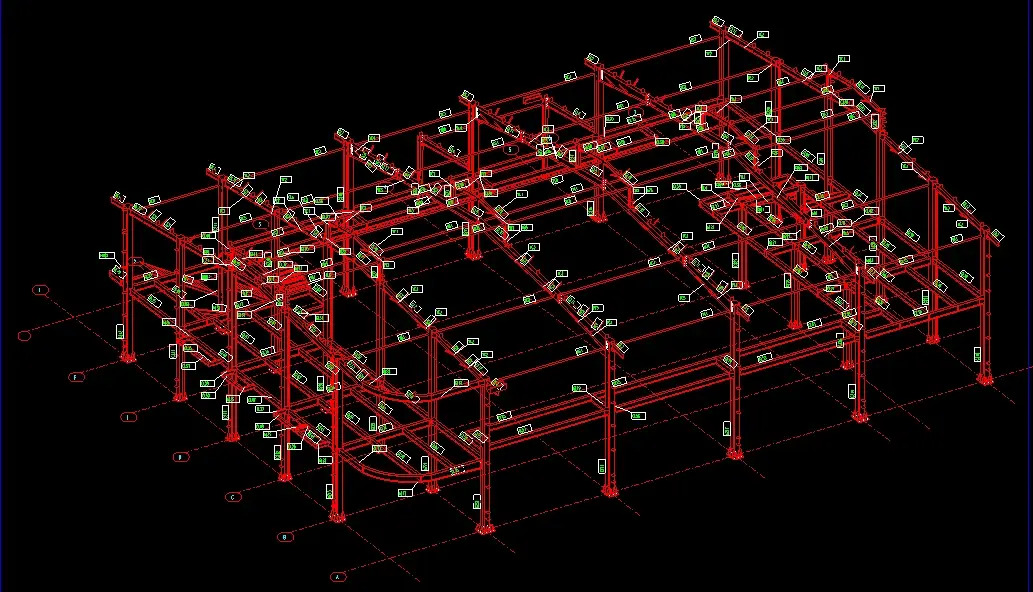

prefabricated structural workshop

| Categories | Steel Structure Buildings |

|---|---|

| Brand | ZYM steel structure building Manufacturer |

| Model | ZYM1 |

| Name | Indonesia steel structure warehouse workshop |

| Key word | Indonesia steel structure workshop with office |

| Design | 3D max,CAD for steel structure frame |

| Material | Q235,Q345B,SS400 steel structure |

| Foof | Galvanized color sheet or sandwich panel |

| Wall | Galvanized sheet for steel structure workshop |

| Place of project | Indonesia steel structure workshop and warehouse |

| Delivery time | 30 days after steel structure drawing confirmation |

| Package | Steel structure frame pallet for 40HQ container |

| Application | workshop,warehouse,office,commercial bulding,shop |

| FOB port | Qingdao Guangdong Shanghai |

| Terms of Payment | L/C, D/A, Western Union, T/T |

| Update Time | May 18,2024 |

ZhengYuanming Construction Engineering Co., Ltd. now is one the prestigious company specializing in Steel Structure | new design steel structure workshop,Workshop Frame,prefab factory steel structure warehouse design,cheap warehouse,two story steel structure warehouse,high quality light steel warehouse workshop,sandwich panels workshop.All of our products comply with international quality standards and clients come from a variety of different markets throughout the world.such as Ukraine etc

| Product name |

prefabricated structural workshop |

|---|---|

| Brand Name |

ZYM |

| Model Number |

STEEL - 01 |

| Material |

Steel column base,steel truss,Anti-rust paint etc |

| Brand |

ZYM prefabricated structural workshop Manufacturer |

| Tolerance |

±1% |

| Keyword |

steel structure prefabricated workshops,storage steel structure warehouse,steel structure workshop fabricate |

| Material |

Q235,Q345B,SS400 steel structure |

| Delivery time |

30 days after steel structure drawing confirmation |

| Certificate |

PHI,TUV,BV,CE etc. |

| Package |

Steel structure frame pallet for 40HQ container |

| Application |

a building made with steel structure,hot sale light steel structure warehouse,steel frame building house,space frame steel structure warehouse |

| Processing Service |

Bending, Welding, Decoiling, Cutting, Punching |

| FOB port |

Qingdao Guangdong Shanghai |

| Terms of Payment |

L/C, D/A, Western Union, T/T |

| FOB port |

Qingdao Guangdong Shanghai |

| Processing Service |

Bending, Welding, Cutting, Punching, Pre-assembling, Painting |

| Project Solution Capability |

graphic design, 3D model design, total solution for projects |

| Main Materials |

light steel construction |

| Color |

Request, colorful |

| Design Style |

Modern |

| Characteristics |

Safe foundation, anti-seismic and windproof |

| Sales country |

Mongolia,Iran,Faroe Islands,Botswana |

prefabricated structural workshop For further information feel free to contact us

specially used for steel structure factory, color steel plate V840 and 950 color steel plate for warehouse

Project Name: prefabricated structural workshopRecently, multiple steel structure projects undertaken by our company are steadily advancing and continuously making new progress.The company's project department and steel structure processing plant seize the golden period of construction and ensure the perfect performance of the project.prefabricated structural workshop services FAQs GuideAre you looking for a quick review guide about prefabricated structural workshopservices?An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding prefabricated structural workshop services.Let’s continue!

2.How does the structural integrity of a prefabricated structural workshop improve safety?

3.What safety precautions should be taken when working on a steel structure building?

4.What is the typical cost of maintenance for a steel structure building?

5.What is the maximum height that can be achieved with a ?

6.What kind of company you are?

7.What type of foundation is required for a steel structure building?

8.Can prefabricated structural workshop be customized to fit specific design requirements?

9.How does the weight of a steel structure building affect site preparation and construction?

1.prefabricated structural workshop What are the benefits of using steel as a construction material for buildings?

We pay attention to the introduction and training of talents, scientifically regulate the management system, and focus on cultural construction and team cohesion. 1. Durability: Steel is one of the most durable construction materials available, and it can withstand extreme weather conditions and heavy loads. 2. Strength: Steel is incredibly strong and can support large structures without the need for additional support. 3. Fire Resistance: Steel is non-combustible and can provide a high level of fire resistance. 4. Cost-Effective: Steel is a cost-effective construction material, as it is relatively inexpensive and can be used in a variety of applications. 5. Versatility: Steel can be used in a variety of applications, from residential homes to large commercial buildings. 6. Eco-Friendly: Steel is a recyclable material, making it an environmentally friendly choice for construction.

2.How does the structural integrity of a prefabricated structural workshop improve safety?

We are a new prefabricated structural workshop manufacturer. The structural integrity of a steel structure building improves safety by providing a strong and stable framework that can withstand the forces of nature, such as wind, snow, and earthquakes. Steel is a strong and durable material that is resistant to corrosion and can be designed to meet specific structural requirements. Steel structures are also fire-resistant, which helps to protect occupants in the event of a fire. Additionally, steel structures are often designed with redundancy, meaning that if one part of the structure fails, the other parts can still support the building. This helps to ensure that the building remains standing and safe for occupants.

3.What safety precautions should be taken when working on a steel structure building?

We have established a good reputation and reliable partnerships within the prefabricated structural workshop industry. 1. Wear appropriate safety gear, such as hard hats, safety glasses, and steel-toed boots. 2. Use appropriate fall protection equipment, such as safety harnesses and lanyards. 3. Use appropriate tools for the job, such as wrenches, hammers, and saws. 4. Secure all tools and materials to prevent them from falling. 5. Follow all safety protocols and procedures. 6. Inspect the structure for any signs of damage or wear before beginning work. 7. Be aware of your surroundings and watch out for any potential hazards. 8. Use appropriate lifting techniques to prevent injury. 9. Use appropriate scaffolding and ladders to reach higher areas. 10. Disconnect all power sources before beginning work.

4.What is the typical cost of maintenance for a steel structure building?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system. The cost of maintenance for a steel structure building can vary greatly depending on the size and complexity of the building. Generally, the cost of maintenance for a steel structure building is between 1-2% of the total cost of the building. This cost includes regular inspections, painting, and repairs.

5.What is the maximum height that can be achieved with a ?

We focus on providing high prefabricated structural workshop quality products and services. The maximum height of a steel structure building is determined by the strength of the steel used, the design of the building, and local building codes. Generally, steel structures can reach heights of up to 30 stories or more.

6.What kind of company you are?

ZYM Team Group focus on creating and protecting value. We offer the full range of steel structure products, from steel material to highly engineered building systems, as well as accessories. Our full production line offers high-quality products at competitive prices. We pay attention to every little detail to ensure our steel structure more perfect. ZYM has three modern base centers, one center is responsible for design and R&D, one center handles production ,one center is for the sales and service.The group maintains production facilities for high-quality prefabricated steel,steel structure with an annual output of 50,000-60,000 tons of steel structure.

7.What type of foundation is required for a steel structure building?

We are a professional prefabricated structural workshop company dedicated to providing high quality products and services. The foundation type required for a steel structure building will depend on the size and type of building, as well as the soil conditions of the site. Generally, steel structure buildings require a concrete slab-on-grade foundation, a shallow foundation, or a deep foundation.

8.Can prefabricated structural workshop be customized to fit specific design requirements?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market. Yes, steel structure buildings can be customized to fit specific design requirements. Steel structure buildings are highly customizable and can be designed to meet the exact needs of the customer. Steel structure buildings can be designed to fit any size, shape, or style, and can be customized with a variety of features such as windows, doors, insulation, and more.

9.How does the weight of a steel structure building affect site preparation and construction?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of prefabricated structural workshop products. The weight of a steel structure building affects site preparation and construction in several ways. First, the weight of the steel structure must be taken into account when designing the foundation and other structural elements. The foundation must be designed to support the weight of the steel structure, and the soil must be able to bear the load. Additionally, the weight of the steel structure must be taken into account when designing the crane and other lifting equipment used to move the steel structure into place. Finally, the weight of the steel structure must be taken into account when designing the temporary bracing and other support systems used during construction.

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings